- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Theknoloji e tsoetseng pele

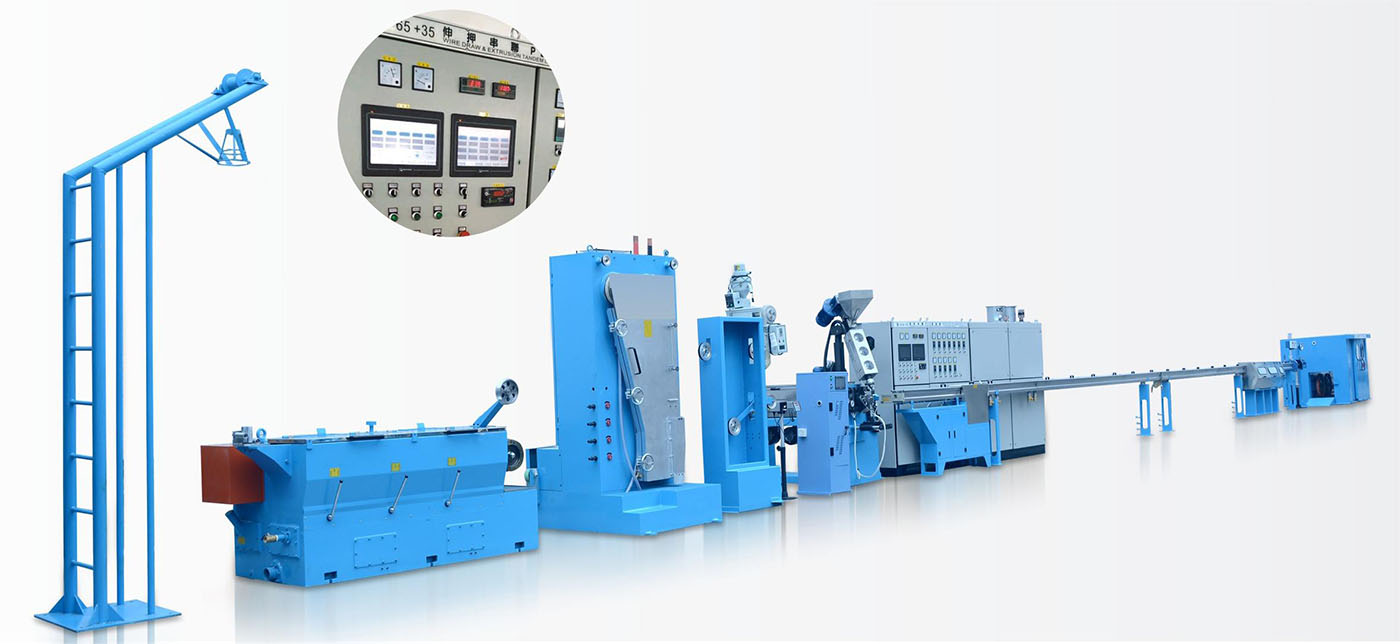

Tandem Line Extrusion Line: The Ultimate Solution for Advanced, High-Performance, Multifunctional, and Reliable Extrusion

Joaloka moetsi ea ka sehloohong oa lisebelisoa tsa extrusion, re motlotlo ho hlahisa Tandem Line Extrusion Line ea rona, e leng tharollo ea morao-rao bakeng sa litlhoko tse tsoetseng pele tsa extrusion.E etselitsoe ho finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng, katleho, le ho feto-fetoha ha maemo, Tandem Line Extrusion Line ea rona ke khetho e nepahetseng bakeng sa mefuta e mengata ea likopo, ho tloha ho tse bonolo ho ea ho tse rarahaneng, le ho tloha ho tse nyenyane ho isa ho tse kholo.

✧ Ts'ebetso e Phahameng

Tandem Line Extrusion Line ea rona e etselitsoe ts'ebetso e phahameng, e fana ka lebelo le ikhethang, ho nepahala le tlhahiso.Ka li-motor tsa eona tse matla, likarolo tse matla, le moralo o ntlafalitsoeng, mohala oa rona o khona ho sebetsana le mesebetsi e boima ka ho fetisisa ea extrusion habonolo.Hore na o hloka ho hlahisa lihlahisoa tse ngata tse bonolo kapa li-profile tse rarahaneng tse nang le mamello e tiileng, mohala oa rona o ka fana ka liphetho tse ikhethang.

✧ Multifunctionality

Tandem Line ea rona Extrusion Line e feto-fetoha haholo 'me e ka hlophisoa ho fihlela litlhoko tse ngata tsa tlhahiso.Ka moralo oa eona oa modular, re ka etsa mohala oa rona hore o lumellane le litlhoko tsa hau tse ikhethileng, ho tloha mofuteng oa thepa eo u e sebelisang ho ea ho sebopeho le boholo ba sehlahisoa sa ho qetela.Hore na o hloka ho ntša PVC, PE, PP, ABS, kapa lisebelisoa tse ling, mohala oa rona o ka sebetsana le tsona kaofela.

✧ Ho tšepahala

Tandem Line ea rona Extrusion Line e hahiloe hore e tšoarelle, e nang le likarolo tsa boleng bo holimo le kaho e matsutla e ka mamellang le maemo a thata ka ho fetisisa a tlhahiso.Re sebelisa feela lisebelisoa le likarolo tse ntle ka ho fetisisa, 'me mohala oa rona o lekoa ka thata ho netefatsa hore o finyella litekanyetso tsa rona tse tiileng tsa boleng.Ho feta moo, re fana ka ts'ebeletso le ts'ehetso e felletseng ho netefatsa hore mohala oa hau o lula o sebetsa hantle le ka katleho.

✧ Qetello

Qetellong, Tandem Line Extrusion Line ea rona ke tharollo ea mantlha bakeng sa extrusion e tsoetseng pele, e sebetsang hantle, e sebetsang ka bongata le e tšepahalang.Ka theknoloji ea eona e tsoetseng pele, ts'ebetso e phahameng, ho feto-fetoha ha maemo, le ho ts'epahala, mohala oa rona o ka u thusa ho fihlela sepheo sa hau sa tlhahiso le ho lula pele ho tlholisano.Ikopanye le rona kajeno ho ithuta haholoanyane ka Tandem Line Extrusion Line ea rona le hore na e ka tsoela khoebo ea hau molemo joang.

Litlhaloso tsa Tekheniki

| Tlhaloso | Tlhaloso |

| Lintho tse bonahalang | PVC, PE, LDPE |

| Kondatara ea koporo e kenang φ[mm] | 2.5~3.0 |

| Sehlahisoa sa koporo conductor φ[mm] | 0.4 ~ 1.2 |

| Cable e feliloeng [mm] | 0.9~2.0 |

| Lebelo la mola [M/min] | 1200. Max |

Litšobotsi

1. Mohala oa tlhahiso o hlokomela mekhoa e meraro ea ho otlolla, annealing le extrusion ea melamu ea koporo ka nako e le 'ngoe, e leng ho fokotsang haholo litšenyehelo tsa tlhahiso, ho ntlafatsa katleho ea mosebetsi le ho fokotsa tšebeliso ea matla.

2. Moralo o kopaneng oa annealing le preheating mme o hlomelloa ka mokhoa o ikemetseng oa tokiso ea tsitsipano ho etsa bonnete ba hore bolelele ba terata ea koporo le bophara ba conductor ke junifomo;

3. Mochini oa Extrusion o nka hlooho e khethehileng ea mochini ho netefatsa hore concentricity ea terata ea mantlha e fihla ho feta 95% le mohala oa tlhahiso ea lebelo le phahameng.

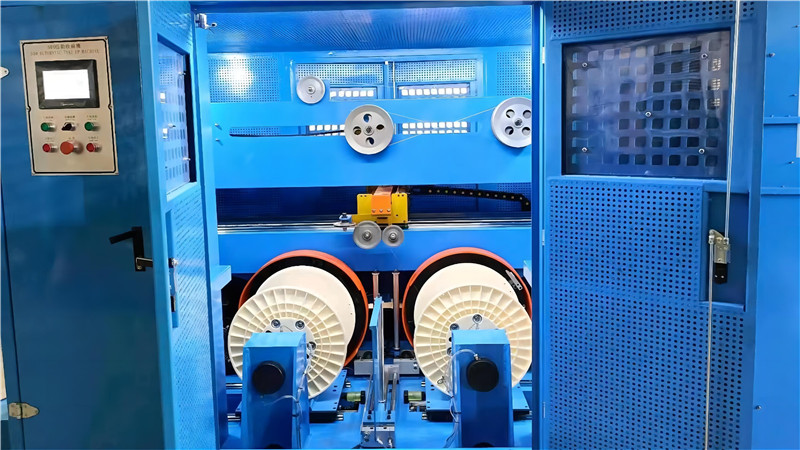

4. Ts'ebetso ea extrusion ha ho etsoa likhoele tsa LAN (katse5, katse6) le likhoele tsa mohala tsa insulative, Sebopeho sa lisebelisoa: e na le lisebelisoa bakeng sa lits'ebetso tse joalo ka ho taka terata, annealing, pre-heating, insulation extruding, tlhahlobo ea bophara ba kantle ho marang-rang, tekanyo ea eccentricity. le ho nka koloi

Tshebetso

Welding

Sepolishe

Mochini

Boring Mill

Ho bokellana

Sehlahisoa se felileng

LBH

A: E, re etsa se latelang:

- Hang ha moreki a re tsebisa hore mochine o behiloe sebakeng se nepahetseng, re tla romela lienjiniere tsa mechine le tsa motlakase ho qala mochine.

-Ha ho na moroalo teko: Ka mor'a hore mochine o kenngoe ka ho feletseng, re qala ho etsa tlhahlobo ea ho se be le moroalo.

-Tlhahlobo ea mojaro: Hangata re ka hlahisa lithapo tse tharo tse fapaneng bakeng sa tlhahlobo ea mojaro.

A: Re tla etsa tlhahlobo e matla ea ho leka-lekanya, tlhahlobo ea boemo ba boemo, teko ea lerata, joalo-joalo. Ts'ebetsong ea tlhahiso.

Kamora ho phetheloa ha tlhahiso, hangata re etsa ts'ebetso e se nang moroalo mochining o mong le o mong pele o beleha.Amohela bareki ho etela.

A: Re na le karete ea mebala ea machaba ea RAL karete ea mebala.U hloka feela ho re bolella nomoro ea 'mala.U ka etsa mochini oa hau hore o lumellane le 'mala oa feme ea hau.

Karabo: Ehlile, ona ke morero oa rona.Ho ea ka litekanyetso tseo thapo ea hau e lokelang ho li latela le tlhahiso ea hau e lebelletsoeng, re tla rala lisebelisoa tsohle, hlobo, lisebelisoa, basebetsi, lintho tse kenang le lisebelisoa tse hlokahalang ho u etsetsa litokomane.