- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Theknoloji e tsoetseng pele

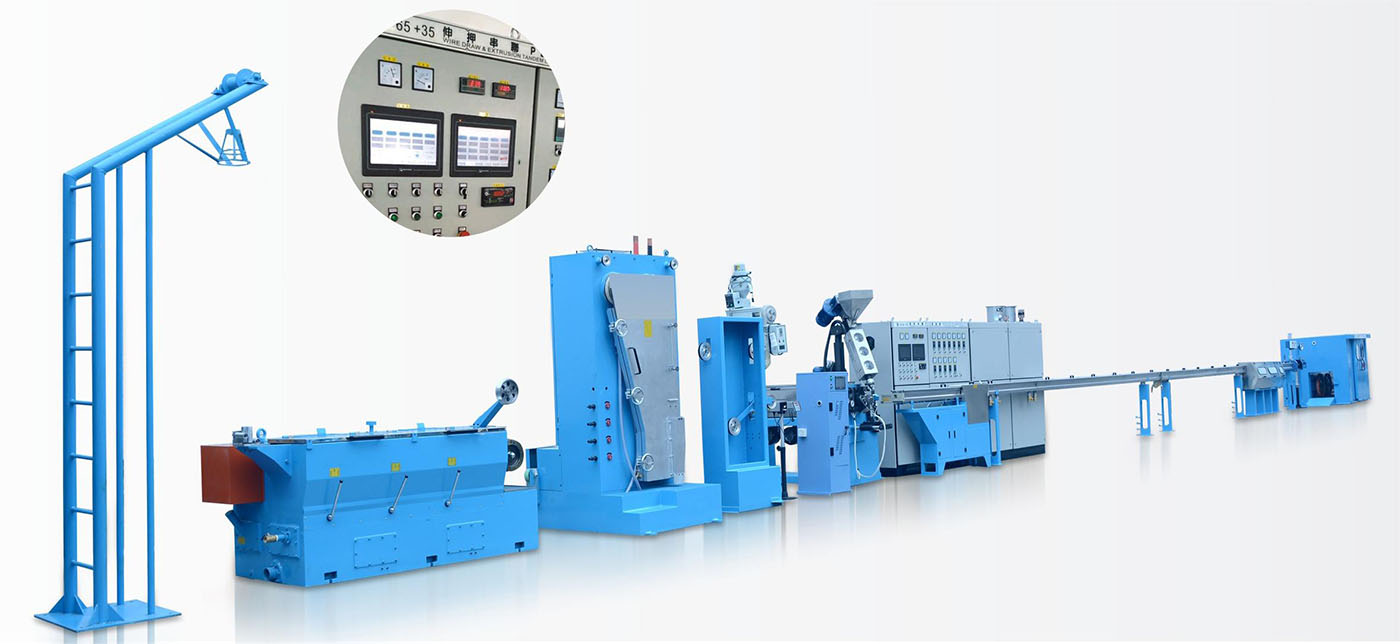

Tandem Line Extrusion Line: The Ultimate Solution for Advanced, High-Performance, Multifunctional, and Reliable Extrusion

Joaloka moetsi ea ka sehloohong oa lisebelisoa tsa extrusion, re motlotlo ho hlahisa Tandem Line Extrusion Line ea rona, e leng tharollo ea morao-rao bakeng sa litlhoko tse tsoetseng pele tsa extrusion. E etselitsoe ho finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng, katleho, le ho feto-fetoha ha maemo, Tandem Line Extrusion Line ea rona ke khetho e nepahetseng bakeng sa mefuta e mengata ea likopo, ho tloha ho tse bonolo ho ea ho tse rarahaneng, le ho tloha ho tse nyenyane ho ea ho tse kholo.

✧ Ts'ebetso e Phahameng

Tandem Line Extrusion Line ea rona e etselitsoe ts'ebetso e phahameng, e fana ka lebelo le ikhethang, ho nepahala le tlhahiso. Ka lijenereithara tsa eona tse matla, likarolo tse matla, le moralo o ntlafalitsoeng, mohala oa rona o khona ho sebetsana le mesebetsi e boima haholo ea extrusion habonolo. Hore na o hloka ho hlahisa lihlahisoa tse ngata tse bonolo kapa li-profile tse rarahaneng tse nang le mamello e tiileng, mohala oa rona o ka fana ka liphetho tse ikhethang.

✧ Multifunctionality

Tandem Line ea rona Extrusion Line e feto-fetoha haholo 'me e ka hlophisoa ho fihlela litlhoko tse ngata tsa tlhahiso. Ka moralo oa eona oa modular, re ka etsa mohala oa rona hore o lumellane le litlhoko tsa hau tse ikhethileng, ho tloha mofuteng oa thepa eo u e sebelisang ho ea ho sebopeho le boholo ba sehlahisoa sa ho qetela. Hore na o hloka ho ntša PVC, PE, PP, ABS, kapa lisebelisoa tse ling, mohala oa rona o ka sebetsana le tsona kaofela.

✧ Ho tšepahala

Tandem Line ea rona Extrusion Line e hahiloe hore e tšoarelle, e nang le likarolo tsa boleng bo holimo le kaho e matsutla e ka mamellang le maemo a thata ka ho fetisisa a tlhahiso. Re sebelisa feela lisebelisoa le likarolo tse ntle ka ho fetisisa, 'me mohala oa rona o lekoa ka thata ho netefatsa hore o finyella litekanyetso tsa rona tse tiileng tsa boleng. Ho feta moo, re fana ka ts'ebeletso le ts'ehetso e felletseng ho netefatsa hore mohala oa hau o lula o sebetsa hantle le ka katleho.

✧ Qetello

Qetellong, Tandem Line Extrusion Line ea rona ke tharollo ea mantlha bakeng sa extrusion e tsoetseng pele, e sebetsang hantle, e sebetsang ka bongata le e tšepahalang. Ka theknoloji ea eona e tsoetseng pele, ts'ebetso e phahameng, ho feto-fetoha ha maemo, le ho ts'epahala, mohala oa rona o ka u thusa ho fihlela sepheo sa hau sa tlhahiso le ho lula pele ho tlholisano. Ikopanye le rona kajeno ho ithuta haholoanyane ka Tandem Line Extrusion Line ea rona le hore na e ka tsoela khoebo ea hau molemo joang.

Litlhaloso tsa Tekheniki

| Tlhaloso | Tlhaloso |

| Lintho tse bonahalang | PVC, PE, LDPE |

| Kondatara ea koporo e kenang φ[mm] | 2.5~3.0 |

| Sehlahisoa sa koporo conductor φ[mm] | 0.4 ~ 1.2 |

| Cable e feliloeng [mm] | 0.9~2.0 |

| Lebelo la mola [M/min] | 1200. Max |

Litšobotsi

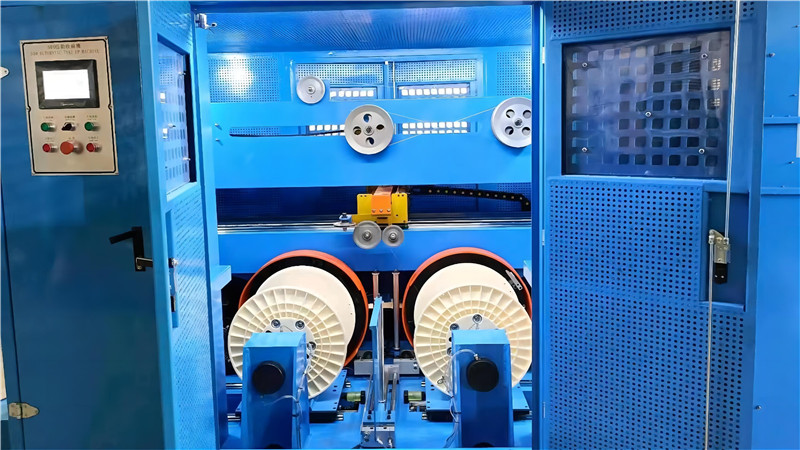

1. Mohala oa tlhahiso o hlokomela mekhoa e meraro ea ho otlolla, annealing le extrusion ea melamu ea koporo ka nako e le 'ngoe, e leng ho fokotsang haholo litšenyehelo tsa tlhahiso, ho ntlafatsa katleho ea mosebetsi le ho fokotsa tšebeliso ea matla.

2. Moralo o kopaneng oa annealing le preheating mme o hlomelloa ka mokhoa o ikemetseng oa tokiso ea tsitsipano ho etsa bonnete ba hore bolelele ba terata ea koporo le bophara ba conductor ke junifomo;

3. Mochini oa Extrusion o amohela hlooho e khethehileng ea mochini ho etsa bonnete ba hore concentricity ea terata ea mantlha e fihla ho feta 95% le mohala oa tlhahiso ea lebelo le phahameng.

4. Ts'ebetso ea extrusion ha ho etsoa likhoele tsa LAN (katse5, katse6) le likhoele tsa mohala tsa insulative, Sebopeho sa lisebelisoa: e na le lisebelisoa bakeng sa lits'ebetso tse joalo ka ho taka terata, annealing, pre-heating, insulation extruding, tlhahlobo ea bophara ba kantle ho marang-rang, tekanyo ea eccentricity. le ho nka koloi

Tshebetso

Welding

Sepolishe

Mochini

Boring Mill

Ho bokellana

Sehlahisoa se felileng

LBH

A: E, re etsa se latelang:

- Hang ha moreki a re tsebisa hore mochine o behiloe sebakeng se nepahetseng, re tla romela lienjiniere tsa mechine le tsa motlakase ho qala mochine.

-Ha ho na moroalo teko: Ka mor'a hore mochine o kenngoe ka ho feletseng, re qala ka ho etsa tlhahlobo ea ho se be le moroalo.

-Tlhahlobo ea mojaro: Hangata re ka hlahisa likhoele tse tharo tse fapaneng bakeng sa tlhahlobo ea mojaro.

A: Re tla etsa tlhahlobo e matla ea ho leka-lekanya, tlhahlobo ea boemo ba boemo, tlhahlobo ea lerata, joalo-joalo. Ts'ebetsong ea tlhahiso.

Kamora ho phetheloa ha tlhahiso, hangata re etsa ts'ebetso e se nang moroalo mochining o mong le o mong pele o beleha. Amohela bareki ho etela.

A: Re na le karete ea mebala ea machaba ea bokahohle ea RAL karete ea mebala. U hloka feela ho re bolella nomoro ea 'mala. U ka etsa mochini oa hau hore o lumellane le 'mala oa feme ea hau.

Karabo: Ehlile, ona ke morero oa rona. Ho ea ka litekanyetso tseo thapo ea hau e lokelang ho li latela le tlhahiso ea hau e lebelletsoeng, re tla rala lisebelisoa tsohle, hlobo, lisebelisoa, basebetsi, lintho tse kenang le lisebelisoa tse hlokahalang ho u etsetsa litokomane.