Mechini e etsang lithapo ka kakaretso e ka aroloa ka mefuta e 'meli: mechini ea ho etsa lithapo le metjhini e lebelo e phahameng ea ho etsa likhoele. Har'a tsona, mochini o etsang li-cage tsa lebelo le phahameng o sebelisoa bakeng sa ho fata lithapo tse kholehileng tsa koporo le mehala ea aluminium e se nang letho. Ho sa le joalo, e ka sebelisoa hape bakeng sa ho etsa thapo ea likhoele tsa motlakase tsa polasetiki, likhoele tse kentsoeng ka rabara le lihlahisoa tse ling.

Selelekela sa Mechini ea ho Laying Lithapo

Mechini e behang lithapo ka kakaretso e ka aroloa ka mefuta e 'meli: mochini oa ho beha lithapo tsa mofuta oa lesaka le mochini o behang mohala oa lebelo le phahameng. Har'a tsona, mochini o behang mohala o lebelo le phahameng o sebelisoa bakeng sa ho hoka likhoele tse koetsoeng tsa aluminium tsa koporo le lithapo tse se nang letho tsa aluminium, hape o ka sebelisoa bakeng sa ho beha thapo ea likhoele tsa matla tsa polasetiki, tse koahetsoeng ka rabara. likhoele le lihlahisoa tse ling.

Tšebeliso ea Mechini ea ho Laying Cable

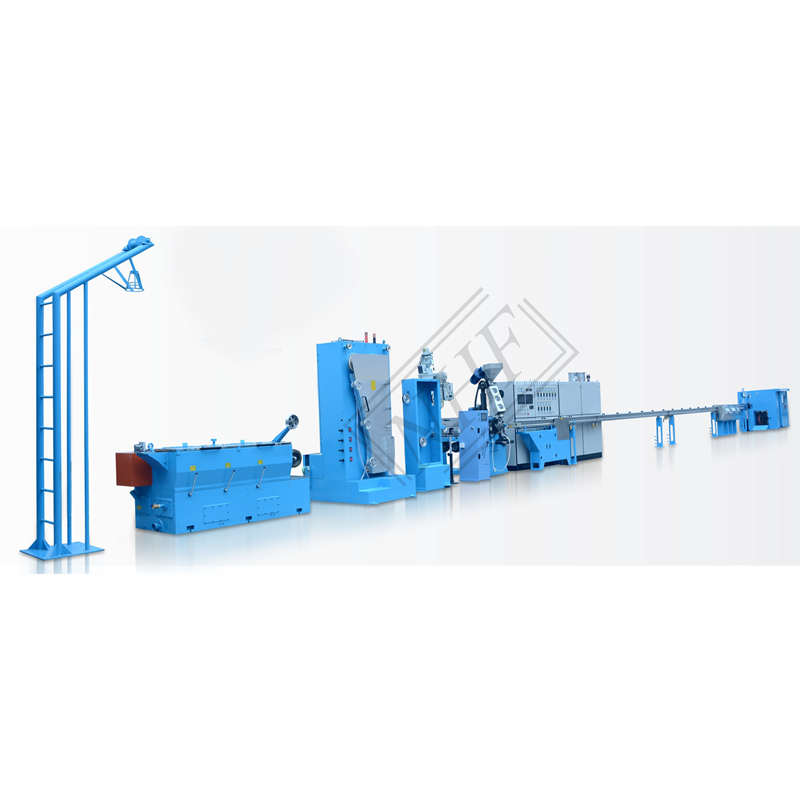

Letoto lena la lihlahisoa li loketse lithapo tsa rabara tse ngata-ngata, lithapo tsa rabara, lithapo tsa lipontšo, lithapo tsa motlakase tsa polasetiki, likhoele tse hokahaneng, likhoele tsa thelefono, lithapo tsa taolo, joalo-joalo tse nang le likarolo tse fapaneng tsa li-cross-sections bakeng sa baetsi ba li-cable laying-up.

Likarolo tsa Mechini ea ho Laying Cable

Letoto lena la mechine ea ho beha li-cable ke lisebelisoa tsa bohlokoa bakeng sa tlhahiso ea li-cable. Lisebelisoa li na le mefuta e mengata e fapaneng le litlhaloso tse felletseng, 'me li sebetsa haholo. Basebelisi ba ka khetha lisebelisoa tsa ho beha li-cable ho latela litlhoko tsa lihlahisoa tsa bona tsa tlhahiso. Thepa e na le mesebetsi ea ho sotha ka morao le ho sotha ho sa fetoheng. Mekhoa ea ho sotha e ka morao e kenyelletsa ho sotha ha selikalikoe sa reverse, ho sotha ka morao ha terene ea lipolanete, le ho sotha ha sprocket reverse. Liforomo tse sothang pele li arotsoe ka letsoho pele ho sotha le motlakase pele ho sotha. The wire spool clamping e arotsoe ka letsoho clamping le motlakase clamping. The take-up e arotsoe ka shaft le mefuta e se nang shaftless.

Sebopeho sa Thepa

Rake ea ho lefa, 'mele oa lesaka le oeleng, sets'oants'o sa terata, mochini o rokang lihlomo, k'haontareng ea bolelele, sesebelisoa sa ho hula, rack, mochini oa phepelo le sistimi ea motlakase.

Mekhahlelo ea mantlha ea tekheniki

- Karolelano ea ho beha lithapo

- Leqhoa le bilikang lebelo

- Sekontiri sa ho beha lithapo

- Lebelo le bilikang hlooho

- Lapping pitch

- Bophara ba lebili la ho hula

- Lebelo la terata e tsoang

Mefuta ea Mechini ea ho Laying Cable

Thepa e sebelisoang bakeng sa ho beha lithapo, ke hore, lisebelisoa tse sothang lithapo tsa terata tse sirelelitsoeng hammoho le ho tlatsa le ho lapping, li bitsoa mochini oa ho beha lithapo. Mechini e behang lithapo e arotsoe ka mofuta o tloaelehileng le mofuta oa meropa. Mechini e tloaelehileng ea ho beha lithapo e kenyelletsa mofuta oa cage le mofuta oa moropa, 'me lebelo la ho beha lithapo hangata le ka tlase ho 10m/min. Mechini e meholo e behang lithapo e entsoe ka mofuta oa meropa 'me e khona ho kenya likhoele tsa mantlha tse tharo, tse nne le tse hlano. Ka mohlala, 1 + 3/1600 le 1 + 3/2400, 1 + 4/1600, 1 + 4/2400 mechine ea ho beha lithapo, 'me li-reel tse lefang ka ho fetisisa ke 1600mm le 2400mm ka ho latellana. Mechini e behang lithapo tse mahareng le tse nyane e entsoe ka mofuta oa lesaka, 'me karolo e ts'oarehang e tšoana le lesaka le thibang la mochini oa terata, o nang le lintlha le mefuta e kang 1 + 6/1000 le 1 + 6/400. Mochini oa ho beha lithapo tsa mofuta oa drum stranding ke sesebelisoa se secha sa ho beha lithapo se nang le katleho e phahameng ea tlhahiso le lebelo ka kakaretso le kaholimo ho 30m/min. E na le mefuta e mengata ea lisebelisoa 'me e ka sebelisoa bakeng sa ho kenya lithapo tsa mefuta e fapaneng ea lithapo tsa motlakase, hammoho le bakeng sa likhoele tsa likhoele tsa puisano, lithapo tsa taolo le li-conductors tsa likarolo tse kholo tsa ultra-high voltage split.

Tšebeliso ea Li-Frequency Converters Mechineng ea ho Laying Lithapo

Sistimi ea ho lefa

Sekhahla sa ho lefa se entsoe ka likarolo tse 12 tsa ho lefa feela. Mathata a ho lefa a hlahisoa ke ho hohlana ha sekhahla sa tšepe khahlano le shaft e potolohang ea reel e lefang ho hlokomela tefo e sa sebetseng ea terata.

Sistimi ea ho hula

Lithapo tse nang le likhoele tse ngata le lirolara tsa khatello ea lebanta li sebelisoa bakeng sa ho hohela ho hlokomela maemo a lebelo la sistimi le referense ea lebelo la sistimi. Mofetoleli oa maqhubu o hlahisa boleng bo sebetsang ba lebelo ho PLC ka sebopeho sa puisano sa RS485. Kamora hore PLC e sebetse data ea seqha se qhekellang le mokhanni oa mochini o nkang, e hlahisa data ho mokhanni oa seqha le mokhanni oa ho nka ka sebopeho sa RS485.

Motantshi

Khatello ea terata e lokisoa ka ho lokisa boima ba terata bo fetang ka lebili la tataiso ea terata kapa ho lokisa khatello ea moea ea cylinder ea moea. Nakong ea ts'ebetso ea mochine oa ho nka mochine, phetoho ea boemo ba motjeko e romelloa ho PLC ho lokisa phetoho ea lebelo la ho nka mochine oa mochine o bakoang ke ho fetoha ha bophara ba maqhubu, kahoo. joalo ka ho elelloa lebelo la mola o sa fetoheng le taolo ea matsoelintsoeke e sa feleng.

Nako ea poso: Nov-28-2024