- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Theknoloji e tsoetseng pele

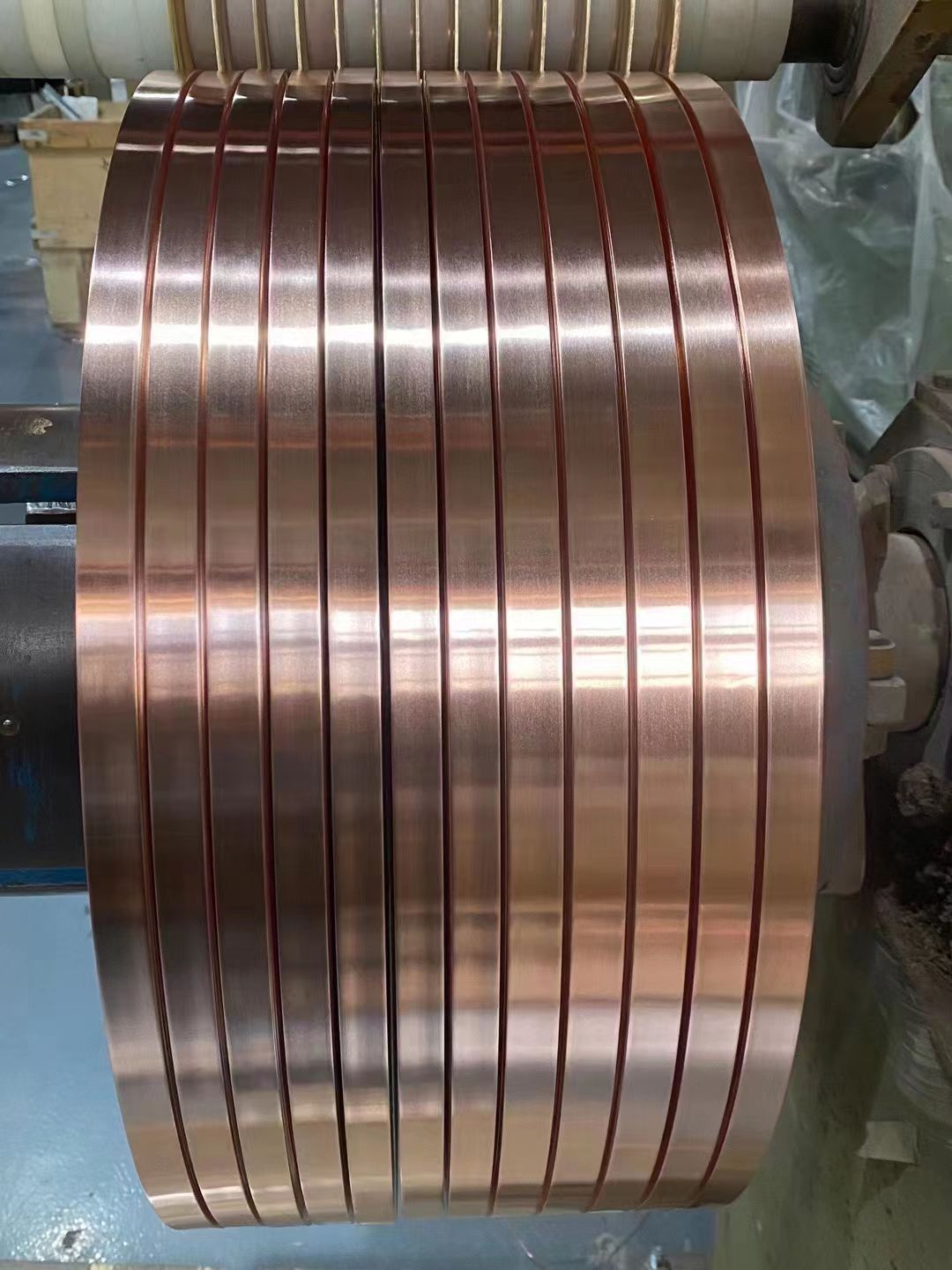

Copper-Aluminium Strip Cladding Production Line ke mokhoa oa tlhahiso ea theknoloji e phahameng o sebelisang theknoloji ea morao-rao ho hlahisa liphahlo tsa boleng bo phahameng. Mohala o sebelisa lisebelisoa tse tsoetseng pele, lisebelisoa le mekhoa ho netefatsa hore sehlahisoa sa ho qetela se tšoana, se nepahetse ebile ha se na liphoso.

✧ Ts'ebetso e Phahameng

Copper-Aluminium Strip Cladding Production Line e hlahisa likhoele tse bonts'ang ts'ebetso e ikhethang lits'ebetsong tse fapaneng. Lithapo tse koahetsoeng li khetholloa ke motlakase o phahameng oa motlakase, thepa e ntle ea phetisetso ea mocheso, le matla a matle a mochine, e leng se etsang hore e be tse loketseng ho sebelisoa indastering e ncha ea betri ea matla.

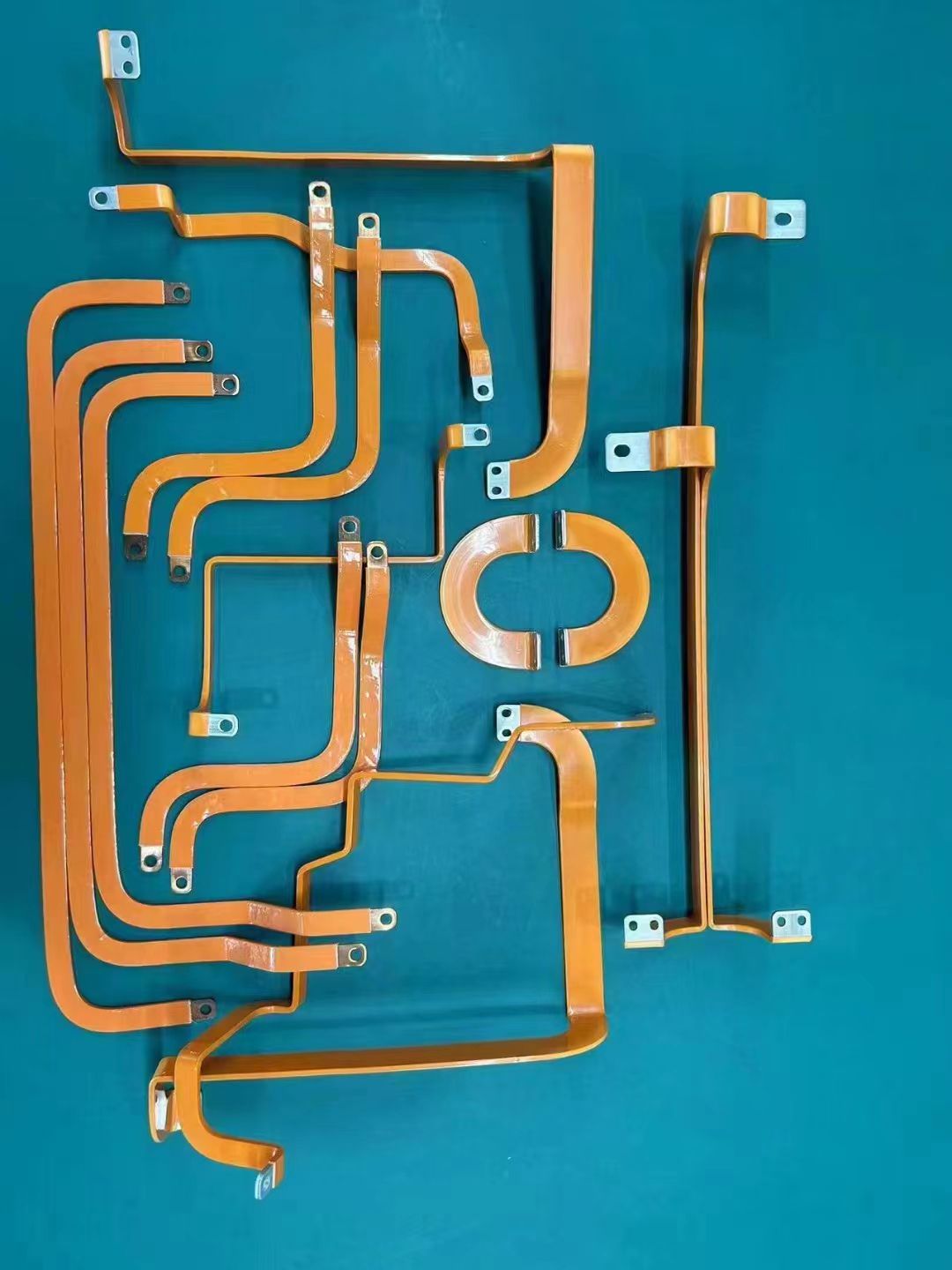

✧ Multi-Functional

Mohala oa Copper-Aluminium Strip Cladding Production Line o etselitsoe ho hlahisa likhoele tse ngata tse sebetsang tse ka sebelisoang mefuteng e mengata ea lits'ebetso. Li-striped strips li ka etsoa ho latela litlhoko tse ikhethileng, ho kenyelletsa boholo, sebopeho le sebopeho. Li ka sebelisoa ha ho hahoa li-module tsa betri, mekoallo ea libese, le likarolo tse ling tse hlokang motlakase o phahameng oa motlakase le ho senya mocheso o sebetsang hantle.

✧ Ho tšepahala

Mohala oa Copper-Aluminium Strip Cladding Production Line o na le theknoloji e tsoetseng pele ea boiketsetso e netefatsang ts'ebetso e tsitsitseng le ts'epo e phahameng. Mohala o entsoe ho nahanoa ka polokeho le katleho, ho fokotsa kotsi ea likotsi le ho netefatsa hore ts'ebetso ea tlhahiso e tsamaea hantle le ka katleho.

✧ Qetello

Qetellong, Copper-Aluminium Strip Cladding Production Line ke tharollo e ncha le e theko e tlaase bakeng sa indasteri e ncha ea matla. Theknoloji ea eona e tsoetseng pele, thepa ea ts'ebetso e phahameng, bokhoni ba mesebetsi e mengata, le ho tšepahala ho etsa hore e be khetho e ntle bakeng sa likhoebo tse batlang ho hlahisa likhoele tsa boleng bo holimo tse finyellang litlhoko tsa 'maraka oa betri. Ka Copper-Aluminium Strip Cladding Production Line, likhoebo li ka fokotsa litšenyehelo, tsa ntlafatsa katleho le tlhahiso, 'me tsa nka monyetla oa tsoelo-pele ea morao-rao ea theknoloji indastering.

Tshebetso

Welding

Sepolishe

Mochini

Boring Mill

Ho bokellana

Sehlahisoa se felileng

Litlhaloso tsa Tekheniki

| Lintho tse koahelang: | XLPE/PVC/PA12. Plasticizing degree 100% |

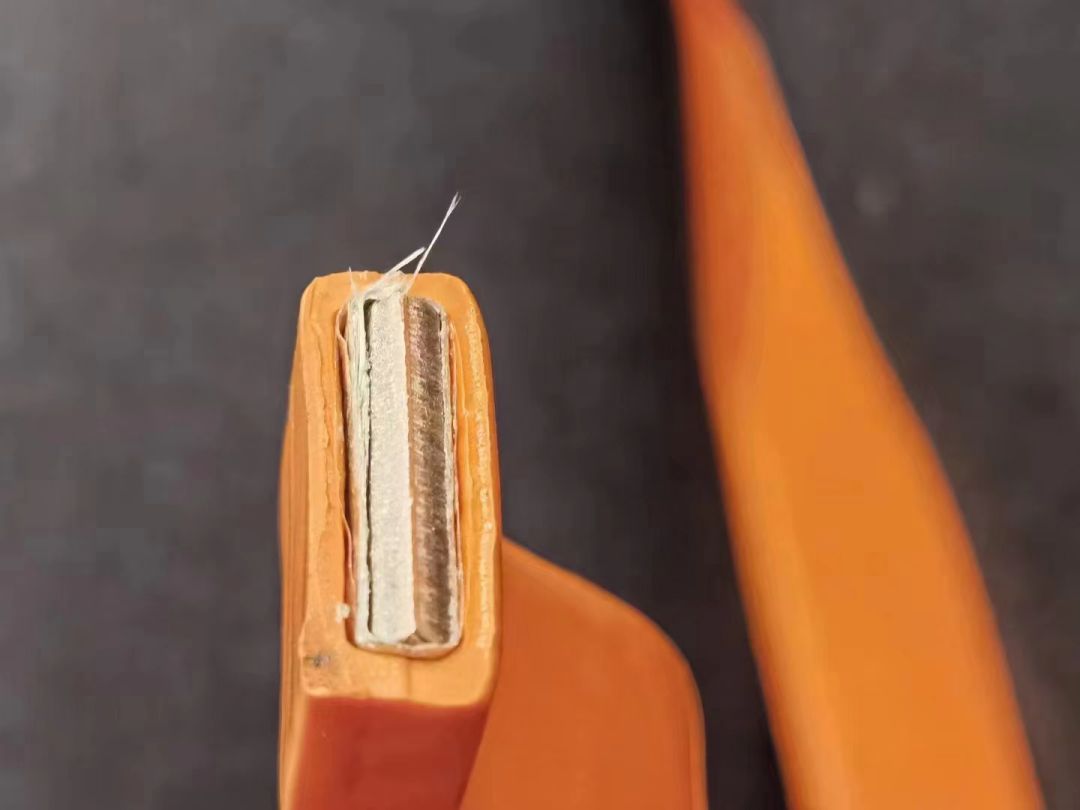

| Boholo ba sekoahelo: | Φ e teteaneng 2 ~ 6mm bophara 14 ~ 50mm; |

| Lebelo le phahameng la ho phuthela: | Φ e teteaneng 2 ~ 6mm bophara 14 ~ 50mm; |

| Bophahamo ba bohareng: | 1000mm |

| Palo ea li-volts: | 3 ph 380V, 50HZ |

LBH

A: E, re etsa se latelang:

- Hang ha moreki a re tsebisa hore mochine o behiloe sebakeng se nepahetseng, re tla romela lienjiniere tsa mechine le tsa motlakase ho qala mochine.

-Ha ho na moroalo teko: Ka mor'a hore mochine o kenngoe ka ho feletseng, re qala ka ho etsa tlhahlobo ea ho se be le moroalo.

-Tlhahlobo ea mojaro: Hangata re ka hlahisa likhoele tse tharo tse fapaneng bakeng sa tlhahlobo ea mojaro.

A: Re tla etsa tlhahlobo e matla ea ho leka-lekanya, tlhahlobo ea boemo ba boemo, tlhahlobo ea lerata, joalo-joalo. Ts'ebetsong ea tlhahiso.

Kamora ho phetheloa ha tlhahiso, hangata re etsa ts'ebetso e se nang moroalo mochining o mong le o mong pele o beleha. Amohela bareki ho etela.

A: Re na le karete ea mebala ea machaba ea bokahohle ea RAL karete ea mebala. U hloka feela ho re bolella nomoro ea 'mala. U ka etsa mochini oa hau hore o lumellane le 'mala oa feme ea hau.

Karabo: Ehlile, ona ke morero oa rona. Ho ea ka litekanyetso tseo thapo ea hau e lokelang ho li latela le tlhahiso ea hau e lebelletsoeng, re tla rala lisebelisoa tsohle, hlobo, lisebelisoa, basebetsi, lintho tse kenang le lisebelisoa tse hlokahalang ho u etsetsa litokomane.