- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Theknoloji e tsoetseng pele

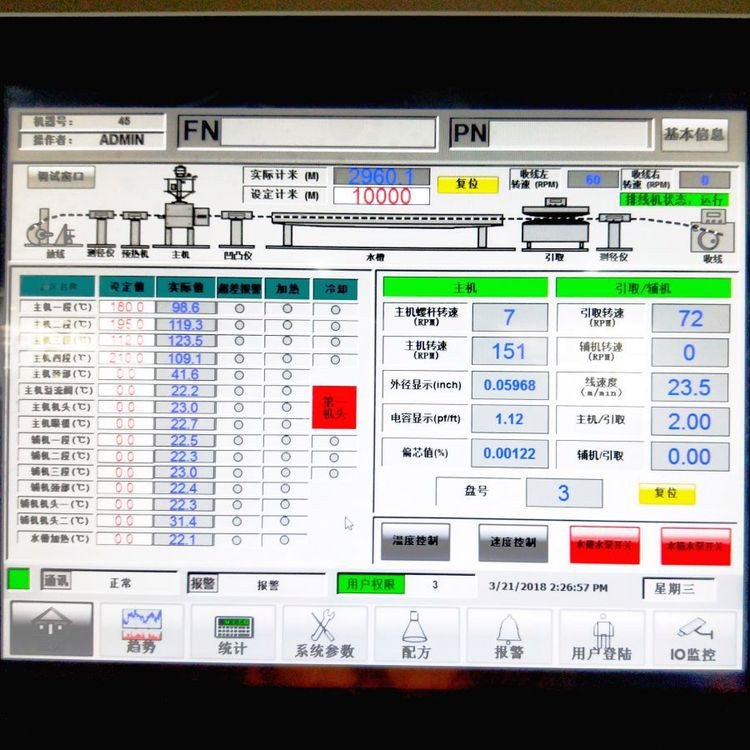

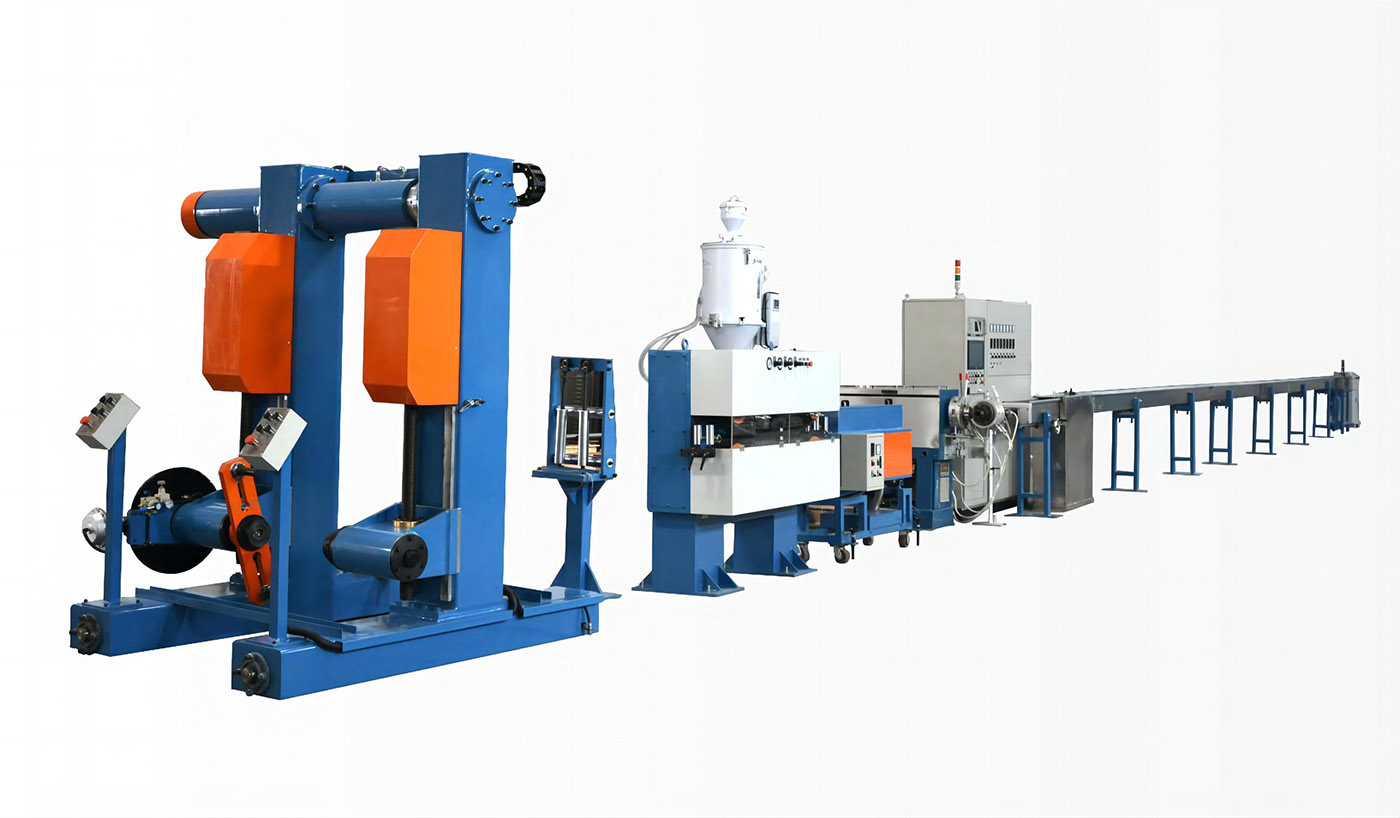

The cable sheathing extrusion line ke sesebelisoa se tsoetseng pele haholo se kenyelletsang theknoloji ea morao-rao ho netefatsa ts'ebetso e sebetsang hantle le e tšepahalang. Mohala o na le litsamaiso tse tsoetseng pele tsa taolo tse lumellang hore ho be le taolo e nepahetseng ea ts'ebetso ea extrusion. Mekhoa ea ho laola e kenyelletsa lisebelisoa tsa mocheso, lisebelisoa tsa khatello, le li-sensor tsa lebelo tse shebellang ts'ebetso ea extrusion le ho etsa liphetoho ha ho hlokahala ho etsa bonnete ba hore ho etsoa lisebelisoa tsa boleng bo phahameng.

Mohala o boetse o kenyelletsa theknoloji e tsoetseng pele ea extrusion e lumellang ho hlahisa lithapo tse nang le bophara bo fapaneng le botenya. Theknoloji ea extrusion e kenyelletsa mefuta e mengata ea li-extrusion dies, lihlooho tsa extrusion, le likarolo tse ling tse lumellang ho hlahisa lithapo tse nang le likarolo tse fapaneng le thepa.

✧ Ts'ebetso e Phahameng

The cable sheathing extrusion line e etselitsoe bakeng sa tshebetso e phahameng le katleho. Mohala o khona ho hlahisa lithapo ka lebelo le phahameng, e leng se tiisang hore ts'ebetso ea tlhahiso e potlakile ebile e sebetsa hantle. Mohala o boetse o etselitsoe ho sebetsana le mefuta e mengata ea boholo ba li-cable le lisebelisoa, e leng se etsang hore e be e fapaneng haholo le ho ikamahanya le litlhoko tse fapaneng tsa tlhahiso.

Mohala o boetse o etselitsoe ho fokotsa litlhoko tsa nako le tlhokomelo. E kenyelletsa likarolo tse kang litsamaiso tsa ho itlotsa ka boiketsetso, mekhoa ea ho itlhoekisa, le likarolo tse ling tse netefatsang hore mohala o sebetsa hantle le ka mokhoa o atlehileng ka nako e telele.

✧ Mesebetsi e mengata

The cable sheathing extrusion line ke sesebelisoa se feto-fetohang haholo se etselitsoeng ho etsa mesebetsi e mengata. Mohala o khona ho hlahisa mefuta e fapaneng ea lisebelisoa, ho kenyelletsa le polasetiki le rabara, e etsang hore e tšoanelehe bakeng sa mefuta e mengata ea lisebelisoa tsa tlhahiso ea cable.

Mohala o boetse o etselitsoe ho hlahisa likhoele tse nang le likarolo le thepa e fapaneng, joalo ka ho hanyetsa lelakabe, ho hanyetsa UV, le thepa e meng. Sena se etsa hore mohala o ikamahanye haholo le litlhoko tse fapaneng tsa tlhahiso le ho netefatsa hore o ka hlahisa likhoele tse fihlelang litlhoko tse khethehileng tsa bareki.

✧ Ho tšepahala

The cable sheathing extrusion line e etselitsoe ho tšepahala le ho tšoarella. Mohala o hahiloe ka lisebelisoa tsa boleng bo phahameng le likarolo tse etselitsoeng ho mamella mathata a ts'ebetso e tsoelang pele. Mohala o boetse o etselitsoe ho fokotsa litlhoko tsa nako le tlhokomelo, e leng se netefatsang hore o sebetsa ka botšepehi ka nako e telele.

Mohala ona o boetse o kenyelletsa likarolo tse tsoetseng pele tsa polokeho tse netefatsang polokeho ea basebelisi le basebetsi ba bang. Likarolo tsa polokeho li kenyelletsa likonopo tsa ho emisa ts'ohanyetso, balebeli ba tšireletso, le likarolo tse ling tse thibelang likotsi le likotsi.

✧ Qetello

The cable sheathing extrusion line ke karolo ea bohlokoa ea thepa bakeng sa tlhahiso ea lithapo tsa boleng bo holimo. E kenyelletsa theknoloji e tsoetseng pele, ts'ebetso e phahameng, ts'ebetso e mengata, le ho ts'epahala ho netefatsa ts'ebetso e sebetsang hantle le e tšepahalang. Mohala o feto-fetoha haholo ebile o ikamahanya le litlhoko tse fapaneng tsa tlhahiso, 'me o etselitsoe ho hlahisa likhoele tse nang le likarolo le thepa e fapaneng. The cable sheathing extrusion line ke sesebelisoa se ikhethileng haholo se bapalang karolo ea bohlokoa ts'ebetsong ea tlhahiso ea cable, 'me ho bohlokoa ho ba le mohala o tšepahalang le o sebetsang ho netefatsa tlhahiso ea likhoele tsa boleng bo holimo.

Litlhaloso tsa Tekheniki

| Mohlala | PVC/LDPE | MDPE/HDPE/XLPE | LSHF | ||||||

| Matla a Motlakase | Max.Sephetho | Screw Speed | Matla a Motlakase [KW] | Max.Sephetho [Kg/H] | Screw Speed | Matla a Motlakase [KW] | Max.Sephetho | Screw Speed | |

| 70 | 37 | 180 | 125 | 37 | 105 | 75 | 37 | 140 | 90 |

| 80 | 55 | 220 | 100 | 55 | 125 | 60 | 55 | 170 | 80 |

| 90 | 75 | 320 | 90 | 75 | 180 | 55 | 75 | 240 | 70 |

| 100 | 90 | 360 | 90 | 90 | 210 | 55 | 90 | 280 | 70 |

| 120 | 132 | 550 | 80 | 132 | 330 | 50 | 132 | 440 | 65 |

| 150 | 160 | 850 | 70 | 160 | 510 | 42 | 200 | 680 | 55 |

| 200 | 200 | 1200 | 60 | 200 | 720 | 40 | 285 | 960 | 50 |

Litšobotsi

1. Thepa ena e sebelisoa bakeng sa extrusion ea mefuta e fapaneng ea PVC, HDPE, XLPE, TPU, LSHF le tse ling tse insulating sheath cables.

2. PVC le LDPE li ka arolelana sekoti sa mofuta o tšoanang oa BM, 'me moralo oa sebopeho o lumellanang le mokhoa oa ho etsa polasetiki ea lapeng o ka etsa hore thepa ea PVC le LDPE e be le matla a holimo a extrusion.

3. LSHF, NYLON le TPU li hloka ho khetha li-screws tse khethehileng tse nang le meralo e fapaneng.

Tshebetso

Welding

Sepolishe

Mochini

Boring Mill

Ho bokellana

Sehlahisoa se felileng

LBH

A: E, re etsa se latelang:

- Hang ha moreki a re tsebisa hore mochine o behiloe sebakeng se nepahetseng, re tla romela lienjiniere tsa mechine le tsa motlakase ho qala mochine.

-Ha ho na moroalo teko: Ka mor'a hore mochine o kenngoe ka ho feletseng, re qala ka ho etsa tlhahlobo ea ho se be le moroalo.

-Tlhahlobo ea mojaro: Hangata re ka hlahisa likhoele tse tharo tse fapaneng bakeng sa tlhahlobo ea mojaro.

A: Re tla etsa tlhahlobo e matla ea ho leka-lekanya, tlhahlobo ea boemo ba boemo, tlhahlobo ea lerata, joalo-joalo. Ts'ebetsong ea tlhahiso.

Kamora ho phetheloa ha tlhahiso, hangata re etsa ts'ebetso e se nang moroalo mochining o mong le o mong pele o beleha. Amohela bareki ho etela.

A: Re na le karete ea mebala ea machaba ea bokahohle ea RAL karete ea mebala. U hloka feela ho re bolella nomoro ea 'mala. U ka etsa mochini oa hau hore o lumellane le 'mala oa feme ea hau.

Karabo: Ehlile, ona ke morero oa rona. Ho ea ka litekanyetso tseo thapo ea hau e lokelang ho li latela le tlhahiso ea hau e lebelletsoeng, re tla rala lisebelisoa tsohle, hlobo, lisebelisoa, basebetsi, lintho tse kenang le lisebelisoa tse hlokahalang ho u etsetsa litokomane.